how do rivets work diagram

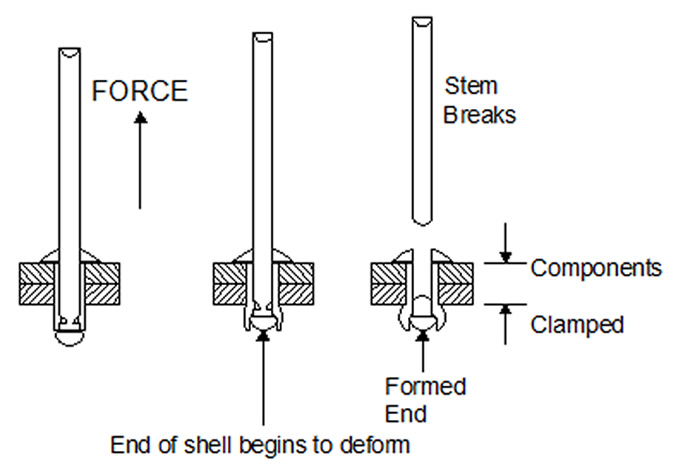

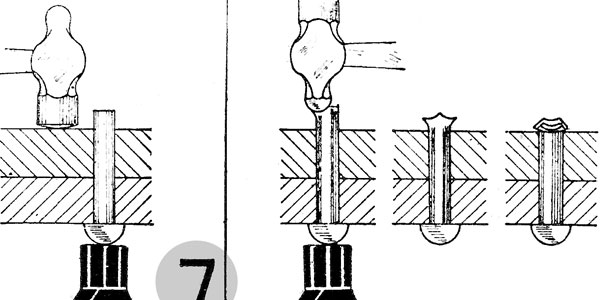

When installed the rivet is either drilled placed or punched into a hole afterwards the tail is then deformed holding the rivet in place. The rivet is often inserted and closed by force so that it completely fills the holes and forms a rigid rivet joint.

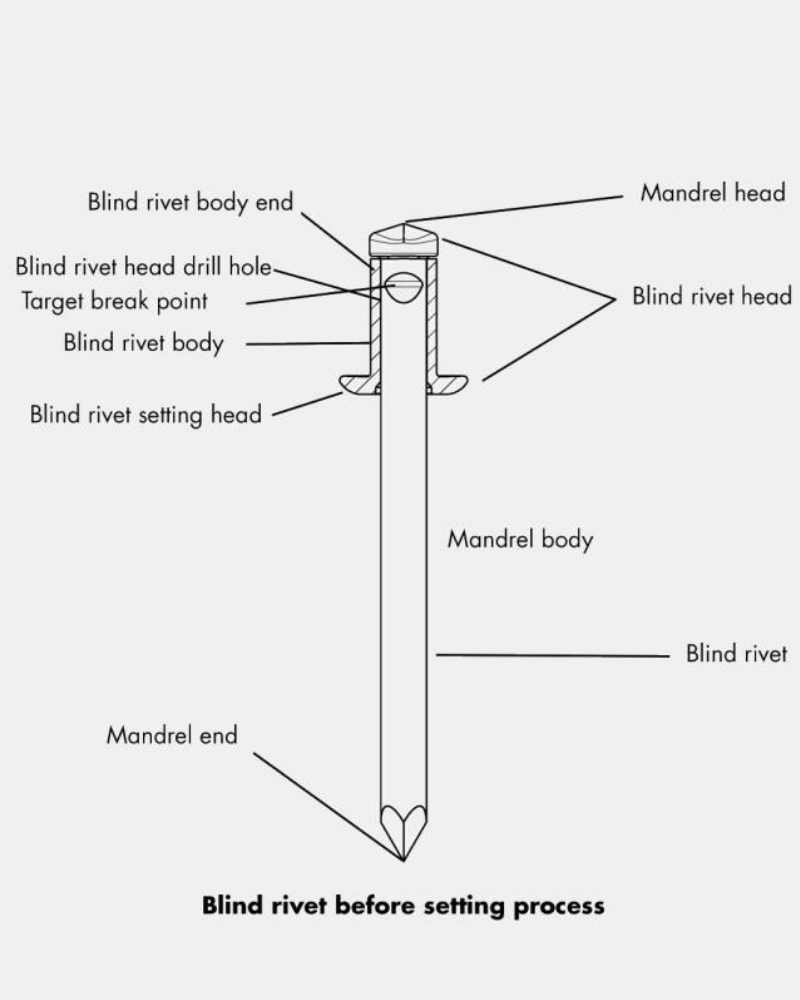

Pop rivets consist of two parts.

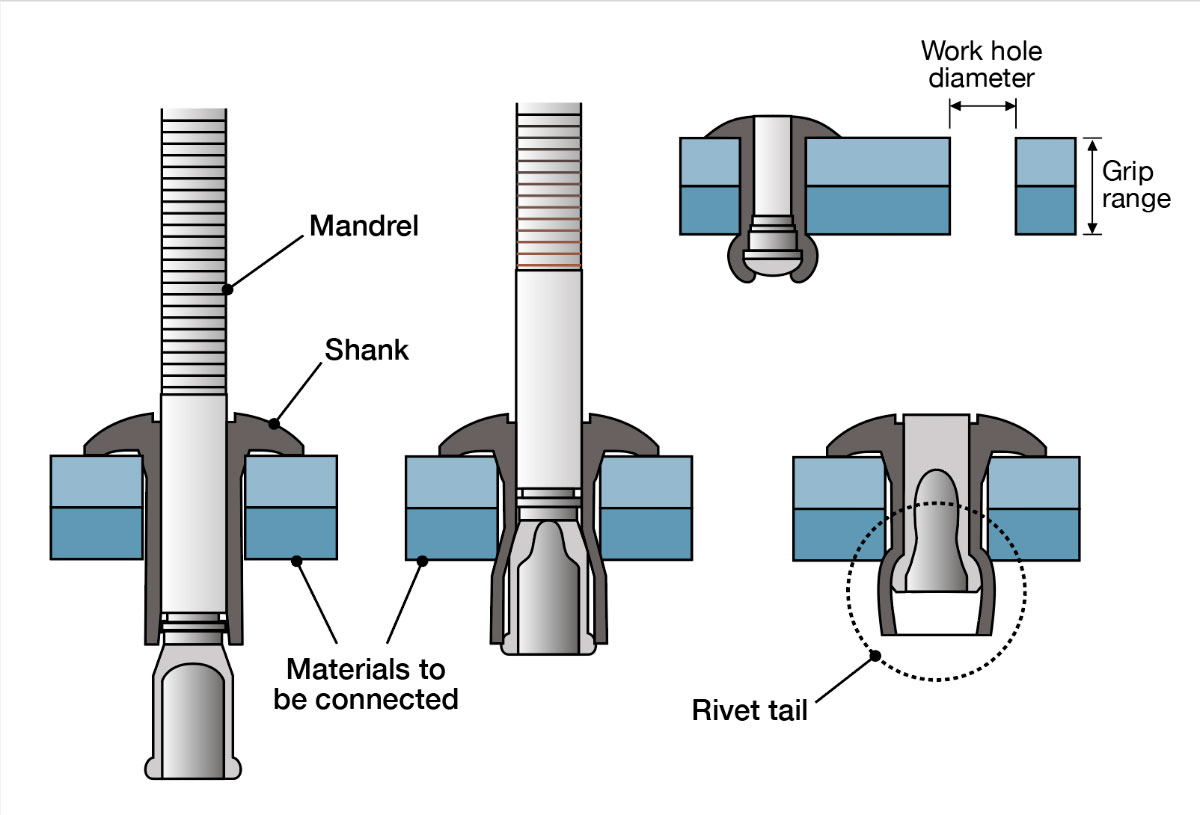

. Gesipa Cordless Rivet Guns are capable of setting 24 to 78mm rivets. Thou shalt use the correct length rivet for the job. In situations where access to both sides of a component is limited a hole is first drilled through the parts to be joined.

A rivet is divided into 3 parts ie the head at one end the tapered tail and shank the portion between the head and tail as shown in the figure. A range of cold rivets are shown below. Learn to use the gun with one.

Because rivet nuts are made to be automated and used in factory settings power installation tools are often mounted to a six-axis robot. Try to hold the gun as close to perpendicular as possible. Its diameter is 16D and its height is 07D.

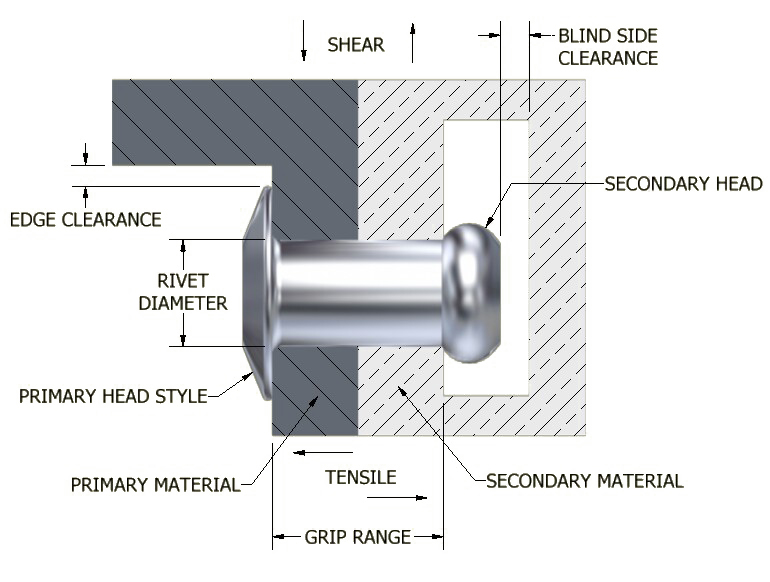

That is why it is widely used in bridges made of iron material. Minimum Diameter of Rivet Shank D 3 x Thickness of the Thickest Sheet That is Being Joined. Use the right tool.

As it is a permanent joint it cannot. The head is of a semi-circle in shape. Snap head or cup head rivets.

Before being installed a rivet consists of a smooth cylindrical shaft with a head on one end. Rivets with this kind of heads are used most of all. How does a Rivnut work.

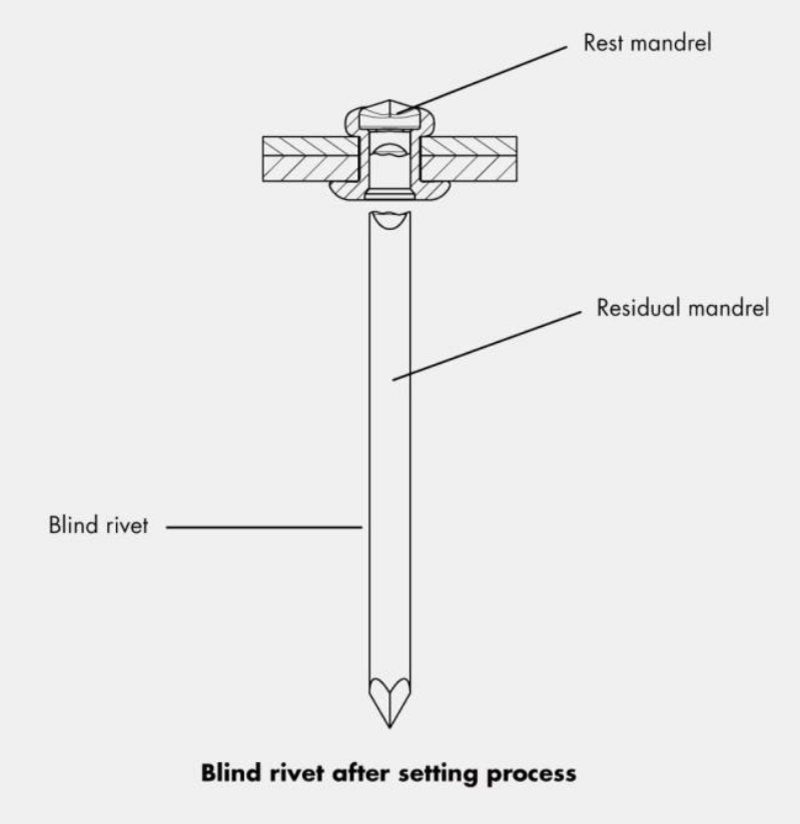

A pop rivet is then inserted through the drilled hole and the rivet body is brought into contact. Your drawings should show how each rivet will look after the rivetting process has taken place. Among the primary benefits of rivet nuts are that they offer a faster assembly and lower installation costs compared to other fasteners.

Rivets are short ductile and cylindrical bars that are used for making a permanent mechanical joint. If you do a lot of work on machines you are going to wind up having a variety of rivet lengths on hand to pick from. Sketch each of the rivets above in position through the holes.

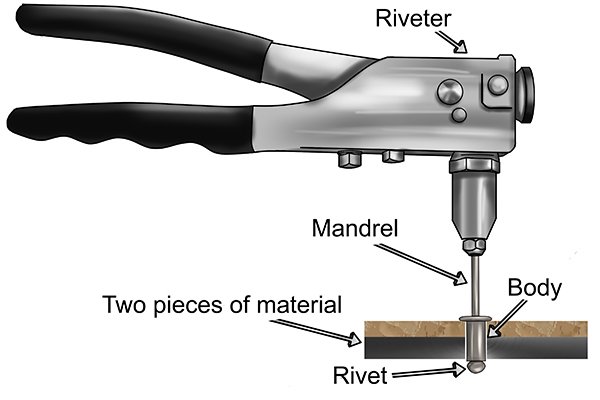

The process of forming a riveted joint is called riveting. The rivet pliers are pushed on to the pin of the rivet and the handles are pulled together. Because it is cable-free Gesipa battery Rivet Guns are ideal for on-site installation or production work.

The two pieces of plastic or aluminium are drilled to a size slightly larger than the rivet. The joints of this rivet are very strong. Construction of aluminum air-frames process is explained by smoothing the wing surface to reduce aerodynamic drag increasing performance and efficiency in f.

A15 D For rivets of diameters of the rivet shank up to 20 mm Length of Rivet Shank L S Allowance A A general rule is that the rivet should have a diameter of at least three times the thickness of the thickest sheet that is being joined. Rivets come in 132 length increments. Exert body weight for holding firmly the gun against the rivet and the work-piece.

This type of rivets is shown in the figure. The diagram below shows two steel plates with four holes drilled through each plate. A straight metal piece will be inserted via the hole or cavity provided for.

Rivets are fasteners used for joining metal sheets and plates in fabrication work such as bridges ships cranes structural steelwork boilers aircraft etc. The pop rivet is passed through both holes in the sheet plastic aluminium. They can install various types of rivets including Bulb-Tite Monobolt and Huck rivets as well as Multi-Grip and standard rivets.

Rivets with this kind of heads are used most of all. 2 What is rivet riveting process definition meaning Image. The rivets are kind of the adjacent surfaces between the two parts to be joined.

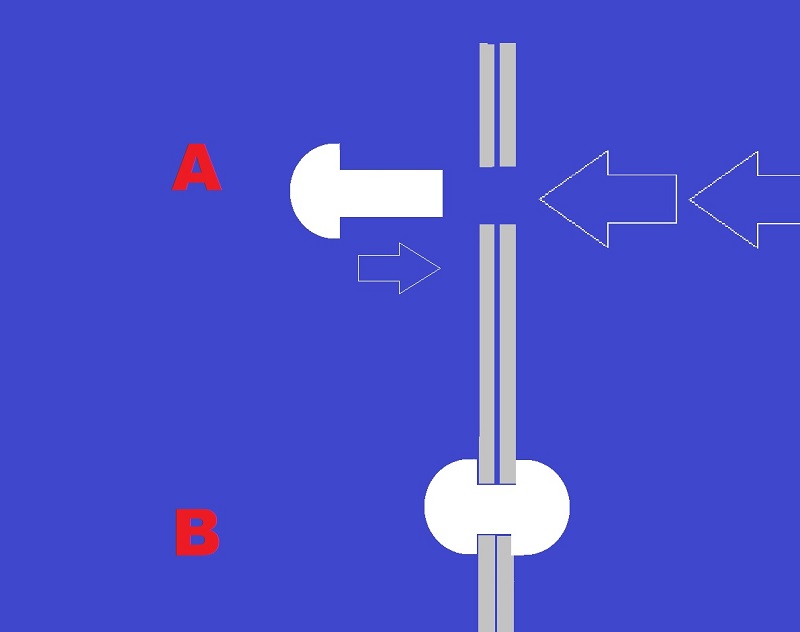

And Riveting is the method of making permanent joints for riveting the plates to be joined are drilled or. The first part is called the rivet body also known as the shell or hat and the second part is called the mandrel also known as the stem. Remember from the diagram above the rivet is to act like a clamp we do not need or want to expand the body size of the rivet at all.

Slide the rivet through the two holes. Just in simple words the parts used to join together with the help of the rivet is known as the riveting process. Adjust the air regulator to help drive the rivet in some seconds.

How Do Rivets Work Fastener Engineering

What Are Structural Rivets Albany County Fasteners

What Is Rivet Definition Types Working Process Engineering Choice

Schematic Diagram Of Friction Self Piercing Riveting Process A Rivet Download Scientific Diagram

What Is A Blind Pop Rivet Gesipa

The Schematic Diagram Of The Riveting Process For The Countersunk Rivet Download Scientific Diagram

How To Pop A Rivet Deals 60 Off Www Ingeniovirtual Com

Riveted Joints Definition Applications Operations Types Studentlesson

How To Pop A Rivet Flash Sales 52 Off Www Ingeniovirtual Com

Pop Rivet Selection Factors Stanley Engineered Fastening

A Schematic Diagram Of The Four Stages Of A Spr Process Download Scientific Diagram

What Is A Blind Pop Rivet Gesipa

Benefits Of High Strength Structural Rivets Goebel Fasteners

How Does A Blind Rivet Work Wonkee Donkee Tools

Optimization Of The Self Pierce Riveting Process With Solid Rivets For Download Scientific Diagram